GRI and KASI Provide Innovative Customer Solution

- BUILD Team

- Dec 16, 2024

- 1 min read

Updated: Jan 6, 2025

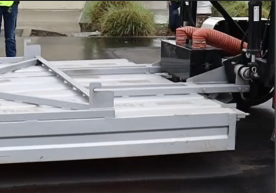

George Reed Inc. was called in to provide repair options for a school’s asphalt playground which had hundreds of raised bubbles in the pavement. While George Reed did not perform the original paving work, they were asked by the prime contractor for help with this unusual problem. The initial recommendation was a full removal and replacement—an estimated $300,000 job. When Steve Genereux, GRI Sacramento Area Manager, asked his team for potential cost saving alternatives, Darin Jourdain (Paving Superintendent), and Rob Roux (Project Superintendent) remembered the recent demo of Reed International’s Kasi Infrared equipment. Thee suggested reheating the asphalt to make it pliable enough to compact the bubbles. By leveraging the Kasi IR-120 Walk Behind and IR-480 Trailer, we delivered a seamless, innovative repair that saved time, money, and resources.

Here’s what the RFC sister companies achieved by thinking outside the box to help a valued customer:

Safety Restored: Trip-and-fall hazards were eliminated.

Cost Savings: The need for full-depth removal and replacement was avoided.

Efficiency: The repairs were completed in just one day.

Seamless Repairs: Minimal impact on existing specialty striping.

Sustainability: Repairing instead of replacing the asphalt saved materials, transportation, and energy.

The Kasi system brought the asphalt to a pliable state, allowing Greg Copper’s crew to level the bubbles quickly and effectively. Its ease of use and outstanding productivity made it the perfect tool for this project, exceeding everyone’s expectations.

This successful job is a good example of how we can work together to provide even greater value to our customers.

Comments